Variable Diameter Air Ring - Dual Directional Flow

Bubble blocking reduction and flatness enhancement system

-

What the upgrade does

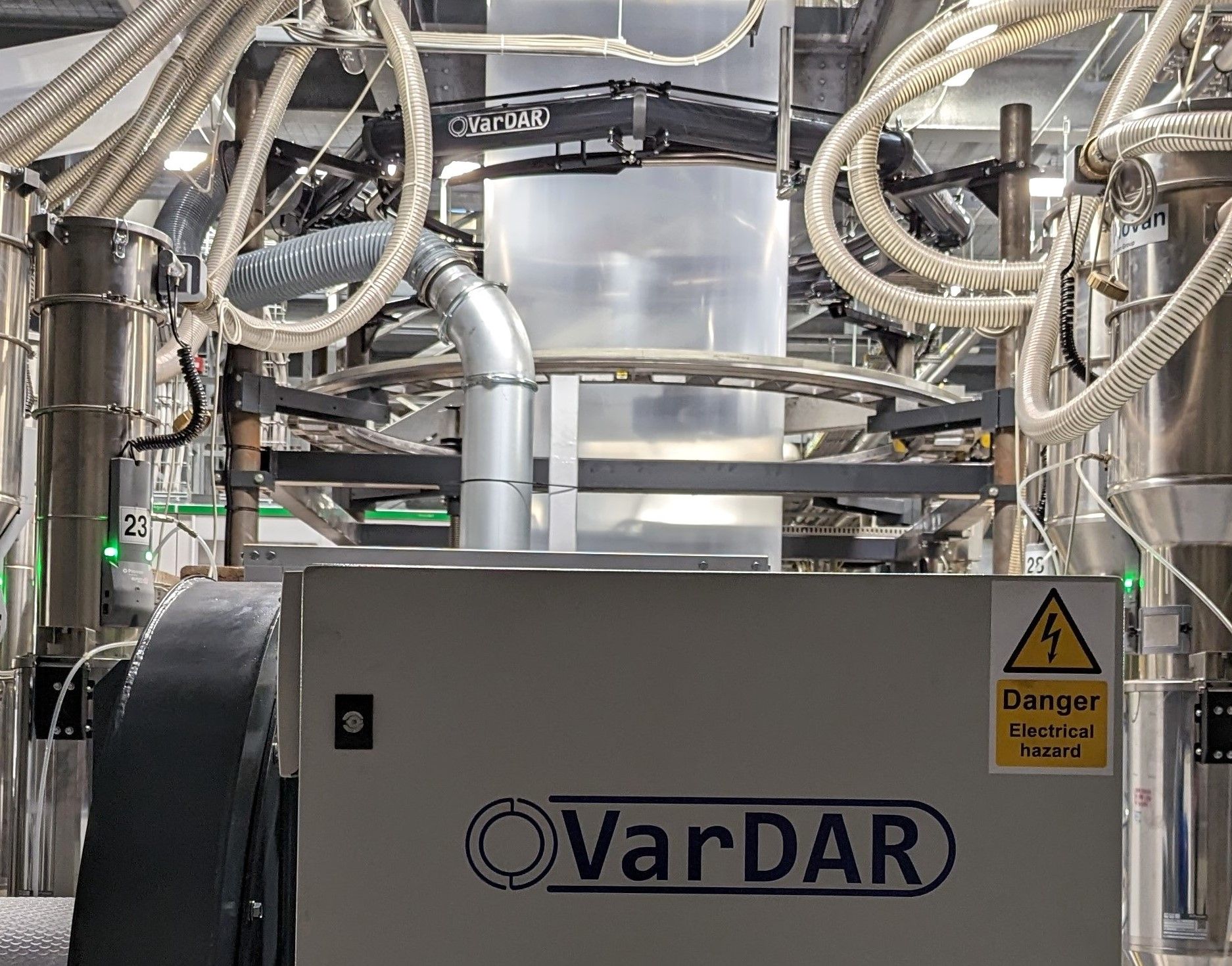

VarDAR or Variable Diameter Air Ring is an innovative system designed to increase productivity of the blown film process by adding additional cooling above the frost line. Reducing such effects as Blocking (Blocking - the inside surface of the bubble sticking to itself at the nip during collapsing making it nearly impossible to open) and reduced tackiness of the bubble outer surface seen when still hot.

VarDAR is especially effective when the height of the blown film line is limited, so provided as a retrofit to existing lines and it is also exclusively available from Hosokawa Alpine for new Installations. it can be seen running in the Hosokawa Alpine Technical Centre, Augsburg, Germany

-

Where the retrofit helps

When you have a product where the blown film line must be slowed down to allow you to achieve a manageable production rate due to blocking, these are products that usually have a softer material on the inner skin layers typically used to help welding in later downstream processes. An extreme example of this is running VLPDE or Plastomers on the Inner bubble surface to create a low heat seal temperature initiation surface for Form Fill and Seal (FFS) applications.

-

The enhancement

VarDAR does not only work on tube products i.e. sacks where the advantages are obvious, but the system is just as effective for the production of single wound sheet. Similar gains in production on sheet products have been seen as the film is much easier to handle down-stream and so runs faster and can enhance flatness whilst improving roll geometery.

Global customers who run VarDAR have not only seen the significant benefit of increased productivity but have also seen reduced scrap levels due to better control of trims and easier splitting of the web, together with an improved aesthetic appearance of the film from reduced stretching and creasing inherently caused by the slitting and separating processes of Films suffering from blocking.

Even material cost savings have been seen by using lower percentages of expensive masterbatches to achieve the same opening characteristics as when using VarDAR.

-

Sizes

VarDAR is available in a range of sizes to cover most applications from small tube lines for shipping sacks, to large machines with web widths up to 4 metres. For the larger lines, the VarDAR assembly frame is available in sections for easier transportation and installation.

-

Benefits

- Dual Directional flow of cooling air along the film surface prior to, through and after the installation to maximise the influence area.

- Non-Contact concentric system ensures even cooling around circumference of bubble.

- Average film temperature drop 10-15 Degree C .

- Reduces the expenditure and lowers the percentage of expensive anti-block additives required.

- Bubble detection, automatically follows the bubble diameter with gap setting.

- Does not interfere with any other line control elements of the blown film line, air ring, Internal bubble cooling and or the auto profile control.

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton